In the dynamic landscape of biopharmaceutical R&D, stable cell lines stand as indispensable engines. They provide the consistent, long-term expression of target proteins—from therapeutic antibodies and enzymes to viral vectors and complex membrane proteins—that is critical for scalable manufacturing, reproducible drug screening, and rigorous functional studies. The journey from a gene of interest to a clonal cell line exhibiting high, stable expression is fraught with technical challenges. Professional stable cell line development services exist to navigate this complexity. By leveraging integrated platforms, optimized workflows, and deep expertise, these services transform a resource-intensive process into a predictable, efficient partnership, accelerating the path from discovery to application.

I.The Critical Role of Stable Cell Lines

A stable cell line, generated by the genomic integration of a transgene, offers irreplaceable advantages over transient expression systems:

⦁ Consistent Production: Enables reliable, long-term protein supply for research, development, and commercial manufacturing.

⦁ Product Quality and Homogeneity: Clonally-derived populations ensure product uniformity, a cornerstone of therapeutic protein quality control.

⦁ Process Scalability: Provides the foundation for robust process development and scale-up to large-scale bioreactors.

⦁ Economic Efficiency: Eliminates the recurring costs of repeated transient transfections for long-term or large-scale applications.

II.A Systematic Development Framework:

⦁ Foundational Strategy: Customized Vector and Host Cell Design

Optimized Expression Construct: Selection of potent promoters (e.g., CMV, EF1α), effective signal peptides, appropriate selection markers (puromycin, hygromycin, GS system), and post-transcriptional regulatory elements.

Strategic Host Cell Selection: Matching the host to the application is key.

HEK293 Systems: Ideal for rapid protein production for research, antigen generation, or viral vector production.

CHO Systems (e.g., CHO-K1, CHO-S): The industry standard for therapeutic protein manufacturing, offering human-like glycosylation, proven scalability, and robust growth in serum-free suspension culture.

Specialized Cell Lines: Such as Vero for vaccine production or insect cells for certain recombinant proteins.

⦁ Precision Gene Delivery: Ensuring Efficient Genomic Integration

Reliable integration of the transgene is achieved through optimized methods:

Lentiviral Transduction: A highly efficient, versatile method suitable for both dividing and non-dividing cells. It enables rapid generation of stable cell pools with high transduction efficiency.

Site-Specific Integration (e.g., CRISPR/Cas9, Flp-In): Technologies that target integration to predefined genomic "safe harbor" loci. This approach yields clones with more predictable and consistent expression levels, minimizing positional effects and gene silencing—ideal for demanding production campaigns.

Advanced Transfection: Optimized electroporation or chemical methods remain viable for specific cell types or non-viral projects.

⦁ The Selection Cascade: From Pool to Monoclonal Clone

Following selection pressure, the meticulous process of identifying the best performers begins:

Guaranteed Monoclonality: Single cells are isolated via limiting dilution or fluorescence-activated cell sorting (FACS), with documented imagery to provide irrefutable proof of clonality for regulatory filings.

High-Throughput Screening: Automated platforms and high-content assays (e.g., plate-based flow cytometry, HTRF/ELISA) enable the rapid screening of hundreds of clones to identify the highest expressors.

⦁ In-Depth Characterization and Stability Assurance

High titer is preliminary; long-term stability and product quality are paramount.

Growth and Expression Stability Studies: Top candidate clones are passaged extensively over many generations in the absence of selection pressure. Growth metrics and product titers are monitored to select the most genetically stable line.

Comprehensive Product Characterization: Expressed proteins undergo thorough analysis—SDS-PAGE, western blot, peptide mapping, glycan profiling, and functional activity assays—to confirm identity, purity, and bioactivity.

⦁ Banking and Quality Control: Delivery of a Ready-to-Use Asset

The selected master clone is used to generate fully characterized cell banks (Master and Working Cell Banks). Rigorous QC testing includes identity confirmation (STR profiling), sterility, mycoplasma, and adventitious agent testing, ensuring the cell line is ready for cGMP manufacturing or critical research applications.

III. Our signature technology platform: Accelerating the development process

⦁ High-Efficiency Enrichment and Screening Platform Based on GFP/FACS

Rapid Enrichment of High-Expression Pools: Following transfection/transduction, directly sort cell populations with high GFP fluorescence intensity via flow cytometry (FACS) to rapidly establish stable mixed pools enriched with high-expression cells, significantly shortening the pre-screening cycle.

Precise Monoclonal Isolation: Perform single-cell sorting (FACS) on the enriched cell pool to ensure 100% monoclonal origin, providing complete electronic sorting records that fully meet regulatory submission requirements from FDA, EMA, NMPA, and other agencies.

Dynamic Stability Monitoring Without Damage: Non-invasively track GFP fluorescence intensity during continuous passage to evaluate clonal expression stability in real time, enabling early identification and elimination of unstable clones.

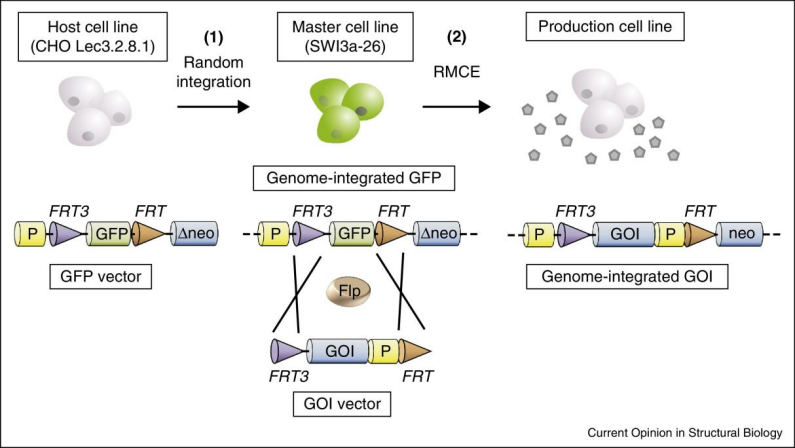

⦁ Rapid Gene Replacement via Flp/FRT Recombinase System

Platform-Based Cell Line Development: We have engineered “platform host cells” containing FRT sites. Through Flp recombinase-mediated site-specific recombination, target gene expression cassettes can be rapidly and efficiently swapped into the same specific genomic location. This method ensures high consistency and predictability of expression levels across different projects, making it particularly suitable for constructing multiple cell lines expressing similar proteins.

This schematic illustrates an advanced workflow for stable cell line development and optimization using a GFP reporter system coupled with Flp/FRT recombination technology.

IV. The Integrated Service Solution: From Concept to Clinic-Ready Cell Banks

❏ Strategic Design & Vector Optimization: We consult on the optimal host cell (CHO-S, CHO-K1, HEK293), expression system, and vector design tailored to your protein's characteristics (secreted, membrane-bound, multi-subunit) and application (research, pre-clinical, GMP).

❏ Cell Banking & Comprehensive QC: The selected top clone is used to generate a two-tiered, fully characterized cell bank (Master Cell Bank MCB / Working Cell Bank WCB). A complete quality control package includes:

⦁ Cell line authentication (STR profiling)

⦁ Sterility, mycoplasma, and adventitious virus testing

⦁ Transgene copy number analysis and sequence verification

⦁ Long-term expression stability report (≥10 generations)

❏ Downstream Process Readiness: Delivered cell lines are adapted to serum-free suspension culture, enabling seamless transfer to shake flask and bioreactor processes for scalable production.

❏ Regulatory Support Documentation: We provide a comprehensive CMC (Chemistry, Manufacturing, and Controls) data package to support IND/CTA filings, including detailed development reports, proof of monoclonality, and complete characterization data.

Proven Applications and Deliverables

V. Our platform is versatile and has been successfully applied to produce a variety of complex proteins:

⦁ Cytokines & Growth Factors: Human Cardiotrophin-1 (CT-1), Oncostatin-M (OSM).

⦁ Antibodies and Fragments: Secreted IgG, scFv, Fab.

⦁ Viral Antigens and Vaccine Targets.

⦁ Toxic or Potent Bioactive Molecules.

Final Deliverables to You Include:

⦁ Fully characterized, clonal research cell line.

⦁ Comprehensive report detailing cloning strategy, screening data, growth profiles, and stability study results.

⦁ Vials of Master and Working Cell Banks (RCB/WCB) with Certificate of Analysis (including sterility, mycoplasma, and identity testing).

⦁ Detailed protocol for induction, expansion, and suspension adaptation.

VI.Partner with Us to Accelerate Your Pipeline

The Inducible Stable Cell Line Development Service is more than just an outsourcing option; it is a strategic partnership that de-risks and accelerates your biologics development. By replacing uncertainty with engineering precision, we empower you to bring novel therapeutics to the market faster.

Contact our cell line development experts today to discuss your specific protein target and discover how our platform can unlock its production potential.